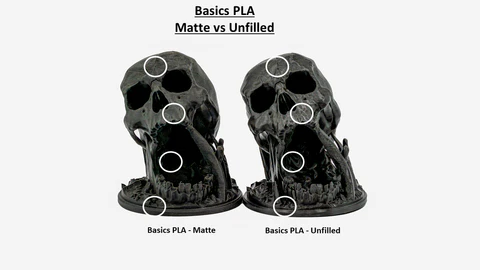

Achieve a stunning, professional look for your 3D prints with ABC3D’s Everyday PLA matte filament. Our specially formulated matte filament is different from standard PLA. As a result, it provides a smooth, non-glossy surface right off the print bed. This helps hide layer lines and gives your creations a premium, textured finish.

Why Choose Our Everyday PLA Matte Filament?

Our Everyday PLA series is exceptionally forgiving and easy to print. In fact, we engineered it to be less stiff and have lower bulk crystallization than standard PLA. This gives it superior impact resistance. Because of this, it’s perfect for functional prototypes and cosplay items that need to be durable. Furthermore, you don’t need any special modifications to your 3D printing setup. It’s designed to be the go-to choice for everyone, no matter which machine you use.

This PLA matte filament is based on Polylactic Acid (PLA). PLA is a popular bioplastic derived from renewable resources like corn starch. Consequently, it’s more environmentally friendly. It also emits significantly less odor during printing compared to other plastics like ABS.

Applications for PLA Matte Filament

- Prototyping

- Cosplay Props and Armor

- Educational Projects

- Architectural Models

- Hobbyist Projects

- Mechanical Parts Testing

- Dental Models

- DIY Home repairs

Everyday PLA Matte Filament Specifications:

- Product Name: Everyday PLA Matte

- Diameter: 1.75 +/- 0.05mm

- Weight: 1 kg

- Length: 335 m

- Density: 1.24 g/cc

- Nozzle Size: ≥ 0.15 mm

- Nozzle Temp: 190 – 230 °C

- Bed Temp: 40 – 60 °C

- Bed Prep: Hairspray, Glue Stick, Polyimide (Kapton) surface

- Layer Height: ≥ 0.1 mm

- Print Speed: 30 – 70 mm/sec

- Fan speed: 50 – 100%

Creative Uses & Tips for PLA Matte Filament

Airsoft, Cosplay & Outdoor Gear: Our Desert Sand, Dark (Army) Green, and Brown filaments are perfect for creating realistic camouflage patterns. For example, you can combine them to make custom parts that blend right into natural environments.

Annealing this PLA Matte Filament

You cannot anneal Matter3D’s Basics PLA series. This is a result of the lower crystallinity of the bulk polymer.

Troubleshooting Your PLA Matte Filament

Issue: My matte prints are stringy

Solution: This is almost always a moisture problem. First, you must dry the material. The additives used for the matte finish are hygroscopic, so drying your spool will eliminate 90% of stringing. Second, try reducing your nozzle temperature by 10°C. This helps because additives can lower the melting point. Finally, you can increase your retraction settings.

Issue: The print is sagging or looks molten

Solution: This PLA matte filament likes a lot of cooling. Therefore, you should increase your fan speed to 100%. This ensures the material cools quickly as soon as it’s printed.

Issue: I can’t get the first layer to stick

Solution: A good first layer is essential. First, make sure your bed is level and clean. Then, use a bed adhesive like a glue stick or hairspray. You should also print the first layer slowly (around 20 mm/s) to ensure it bonds properly.

Quality

We manufacture all our filaments with 5-Axis laser-controlled precision. This process provides the highest class of products for the 3D printing industry.

Technical Data Sheets:

Technical Data Sheet – PLA Everyday Filament

Material Safety Data Sheet:

Material Safety Data Sheet – PLA Filament

PLA Matte Filament: FAQs

1. Is this PLA Matte Filament abrasive?

No. Unlike Carbon Fiber or CNT filaments, the additives used for the matte finish are not abrasive. Therefore, it will not wear down a standard brass nozzle.

2. Is this matte filament stronger than regular PLA?

Yes. We formulate this PLA matte filament with impact modifiers. This makes it less stiff and significantly more durable than standard, brittle PLA. As a result, it’s an excellent choice for functional parts and cosplay props that might be dropped or flexed.

3. How do I get the best matte finish?

The matte finish is consistent across the entire temperature range. However, for the best visual quality, you should print at the lower end of the temperature range (190-210°C). Printing at 100% fan speed also produces the smoothest results.

4. Why is my PLA Matte Filament stringing?

Stringing is almost always a moisture issue. In fact, the additives that create the matte effect are hygroscopic, meaning they absorb moisture from the air. Therefore, you must dry the spool at 50°C for 4-6 hours to remove moisture and stop stringing.

Reviews

There are no reviews yet.